Immersion Type

Metal Machining Liquid, Cutting Fluid, Coolant

I. Main Features

I. Main Features

◆ Compact structure, easy installation and maintenance;

◆ Special parts of industrial chiller are made of special materials with special treatment, corrosion resistance, strong sealing performance;

◆ Reliable performance, stable operation, low noise, high energy efficiency;

◆High-pressure electrostatic spray, beautiful appearance, anti-static, corrosion-resistant;

◆ Low power consumption, environmental protection and energy saving.

II. Applications:

◆CNC lathe, milling machine, broaching machine;

◆CNC Machining center

◆Grinding machine, honing machine;

◆Electric discharge machine, cleaning machine;

◆Hydraulic machines;

III. Functions:

◆To keep machining accuracy subject to the changing liquid temperature;

◆Set up the oil temperature based on the ambient temperature to avoid thermal deformation for the workpieces;

◆Immersion type to keep the chiller from contaminating by the impurities and the cutting powder;

◆Easy to clean, maintain and install;

◆Auto alarming function to reminder users for inspection and maintenance to avoid any damage of industrial chiller/cooling unit.

IV. Technical Specifications

| Model | MC-16-J | MC-25-J | MC-35-J |

| Cooling capacity (W) | 1600 | 2500 | 3500 |

| Input power (KW) | 0.9 | 1.05 | 1.6 |

| Power source | 220-240V/50HZ | ||

| Current (A) | 4 | 4.8 | 5.2 |

| Temperature regulating range (°C) | 5°C~35°C | 5°C~35°C | 5°C~35°C |

| Ambience Temperature (°C) | ≦42°C | ≦42°C | ≦42°C |

| Refrigerant | R22/R134a/R290 | R22 | R22 |

| Weight (kg) | 50 | 52 | 66 |

| Dimension (mm) | 440x420x820 | 465x465x(576+330) | 520x500x970 |

Remarks:

- Cooling Capacity results subject to the ambience temperature at 35°C, oil liquid temp. at 35°C and water liquid at 20°C.

- When the liquid level is below the chilling tube, clotted water on the tube surface will be mixed into the liquid to cause liquid deterioration, thus decreasing the cooling capacity;

- This industrial chiller / cooling unit machine should be used in well-ventilated places free of dust, corrosive gas or debris.

- Do not use corrosive liquid;

- Clean the liquid, filter net and chilling tube regularly, once per month is preferred;

- Clean the condensator regularly, once per half year is preferred;

- Other industrial chiller / cooling unit specifications and sizes can be customizable upon request.

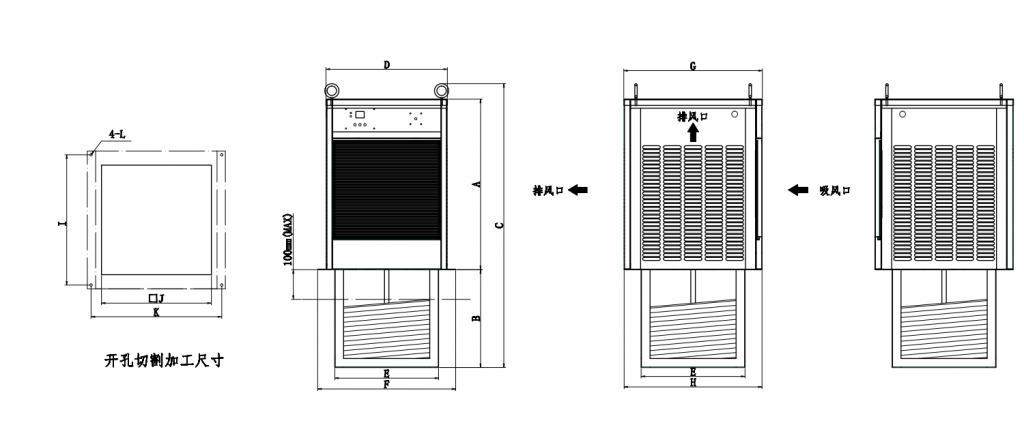

V. Mounting Dimensions of Industrial Chiller / Cooling Unit

| Model | A | B | C | D | E | F | G | H | I | J | K | L |

| MC-16-J | 500 | 300 | 860 | 409 | 350 | 420 | 467 | 465 | 440 | 370 | 440 | M8 |

| MC-25-J | 576 | 330 | 960 | 409 | 350 | 465 | 467 | 465 | 440 | 370 | 440 | M8 |

| MC-35-J | 601 | 400 | 1050 | 512 | 420 | 570 | 603 | 600 | 545 | 440 | 575 | M10 |

VI. Models Instruction

MC – XX – J

(1) (2) (3)

(1)Serial Number:

MC: Immersion type industrial chiller / cooling unit series;

(2)Cooling Capacity(x100W)

XX indicate cooling capacity 100x(XX)=100XX (W)

e.g. XX is 25, it indicates cooling capacity at 100W x 25=2500W

(3) J stands for cooling agent (S for water, Y for oil)