Industrial Water Chillers | Water Cooling Unit

I.Applications

I.Applications

- High speed electro spindle and water-cooled servo motor in machining center

- CNC wire cutting machine, multi-wire cutting machine

- CNC engraving machine, high speed engraving and milling machine

- Varied laser cutting machines

- CNC machine tool torque motor, linear motor

- PCB drilling machine, chamfering machine

- Apparel Machinery, Food Machinery, Plastic Machinery and welding equipment

- Semiconductor manufacturing, optical equipment and laboratory equipment

II.Functions & Features

- Can precisely control the machining temperature, improve the machining accuracy and reduce the cost.

- No cooling tower is needed, saving space.

- Fully enclosed water tank, anti-rust water circulation system.

- The independent water cooler has a complete suction water system. As long as the water pipe is connected, it can work with the equipment.

- To keep machining accuracy subject to the changing liquid temperature;

- The unit is equipped with an automatic alarm function, which can prompt the user to repair the device in a specific way to avoid damage to the machine.

III.Technical Specifications

| Models | WLP-10 | WLP-25 | WLP-35 | WLP-50 | WLP-70 | WLP-100 |

| Cooling Capacity (W) | 1000 | 2500 | 3500 | 5000 | 7000 | 10000 |

| Rated Power (KW) | 0.85 | 1.6 | 2.1 | 2.8 | 4 | 5 |

| Power Source | 380V/50HZ(Compressor 220V/50Hz) | 380V/50HZ | ||||

| Current (A) | 4.2 | 7.8 | 10 | 5.6 | 7.3 | 9.5 |

| Temperature Regulating Range (°C) | 5°C~35°C | |||||

| Working Temperature (°C) | ≦42°C | |||||

| Refrigerant | R22/R134a/R290 | R22 | R22 | R22 | R22 | R22 |

| Weight (kg) | 50 | 62.5 | 65 | 68 | 75 | 80 |

| Dimension (mm) | 385x455x780 | 470x530x950 | 550X530X1050 | 550x600x1050 | 575x655x1200 | 650x730x1200 |

| Pump Head(m) | 25-30 | 25-30 | 25-30 | 25-30 | 25-30 | 25-30 |

| Water Pressure(Mpa) | 0.1-0.3 | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 |

| Water Pump Flux(L/min) | Customizable upon request | 25 | 25 | 25 | 40 | 50 |

| Inlet /Outlet Size(customizable) | G3/8″ | G3/8″-G3/4″ | G3/8″-G3/4″ | G3/8″-G3/4″ | G1″ | G1″ |

| Machine Protection | Compressor overheat protection; Water level and water temperature control; automatic monitoring and protection of water flow | |||||

Remarks:

- Cooling Capacity results subject to the ambience temperature at 35°C, inlet water temp. at 25°C and outlet water temp. at 20°C.

- The water inlet of the water chiller must be 10mm higher than the bottom of the water tank to avoid inhalation of sludge.

- This industrial water chiller / cooling unit machine should be used in well-ventilated places free of dust, corrosive gas or debris.

- Do not use corrosive liquid; It is recommended to use purified water and add a little anti-rust water.

- The operating environment is 5-42°C. The external dimensions and related parameters will be changed subject to the final customer’s request.

- Other industrial water chiller / cooling unit specifications and sizes can be customizable upon request.

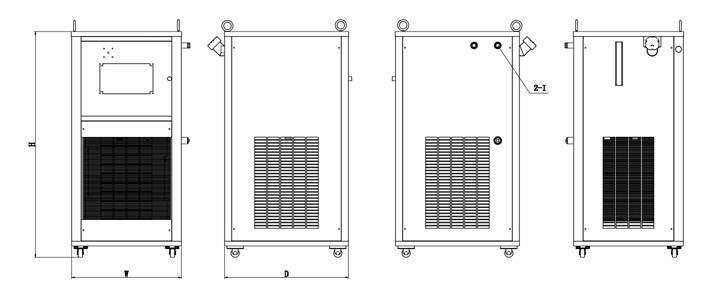

IV. Mounting Dimensions of Industrial Water Chiller / Cooling Unit

| Models | Dimensions | |||

| W | D | H | 2-I (Inlet Outlet size) | |

| WLP-10 | 385 | 455 | 780 | 1/2” |

| WLP-25 | 470 | 530 | 950 | |

| WLP-35 | 550 | 530 | 1050 | |

| WLP-50 | 550 | 600 | 1050 | 3/4” |

| WLP-70 | 575 | 655 | 1200 | |

| WLP-100 | 650 | 730 | 1200 | 1” |

V.Models Instruction

WLP – XX – J

(1) (2) (3)

(1)Serial Number:

WLP: Industrial water chiller / cooling unit series;

W: Water chiller

P: Water tank with pump

(2)Cooling Capacity(x100W)

XX indicate cooling capacity 100x(XX)=100XX (W)

e.g. XX is 25, it indicates cooling capacity at 100W x 25=2500W

(3) X stands for updated product

VI. Instruction on How to Choose Water Chiller

(A) High-speed electro- spindle water chiller:

- Selection method:

(1) Water temperature: spindle cooling water temperature should be controlled at about 25 °C;

(2) Water pressure: the water pressure required for cooling the spindle is about 0.2MPa;

(3) Calculation of heating power of spindle:

P heat = P motor η

P heat – spindle heat kW

P motor – spindle drive motor power kW

η – spindle heat loss efficiency

For high-speed motor spindles, heat loss η = 30% can be calculated (Generally, domestic electric spindle value η = 30%, in Germany, Switzerland and Japan, electric spindle value η = 20%) .

Example: The power of a machine spindle motor is 11kW, the maximum speed is 30000rpm, try to estimate the heat of the machine spindle:

P heat = 11×30% = 3.3 kW

The cooling capacity of WLP-35 is 3.5kw when the water temperature is 25°C and the ambient temperature is 30°C, which is higher than the spindle heating power of 3.3KW. It fully meets the requirements for use; when the water supply pressure is 0.2MPa, the flow rate is 25L/min.

(B) low-speed wire-wound wire cutting machine:

- Selection method:

(1) Calculate the heating power based on the installed power:

P heat = η·P power

P Heat – Heat kW

P-loading – loading power kW

η – heat loss efficiency

Taken η≈20% for the general low speed WEDM.

(2) Calculate heating power based on the rate of increase of water temperature in the working tank

P heat = CP ·m·ΔT/t

P heat—heating power KW

1 kW =860 kcal/h

1 kcal/h = 1.16×10-3 KW

CP———specific heat capacity of constant pressure KJ/Kg·°C

Constant pressure specific heat capacity of water 4.18 KJ/Kg·°C

M——the total amount of water in the tank kg

ΔT – Temperature rise per unit time °C

T(t) – time S

Example: The total water volume of a working fluid tank for a low-speed wire-cut WEDM is 400kg. In normal operation, the water temperature rises from 25°C to 29°C in 40 minutes. The chiller selection method is as follows:

P heat = 4.18 x 400 x (29-25) / (40 x 60) = 2.79 kW

The cooling capacity of the water chiller should be greater than 20% of the heat, and a WLP-35 water chiller can be used.

(C) Laser device:

- Selection method: Calculate the calorific power of the laser according to the photoelectric conversion efficiency of the laser

Calculation formula: P heat = P laser · (1-η)/η

P heat: laser heat (W)

P laser: laser input power (W)

η: laser photoelectric conversion rate (%), determined according to different lasers.

Carbon dioxide laser range: 8%-10%

Lamp pump laser range: 2%-3%

Semiconductor pump laser range: 20%-30%

Fiber laser range: 20%-30%

Example: The output power of carbon dioxide 1000W laser is 1000W, and the photoelectric conversion rate is 9.5%.

P heat = 1000 x (1-9.5%) ÷ 9.5% = 1000×9.5263 = 9526W

The cooling capacity of this water chiller should be greater than the calorific value, for which reference can be made to WLP-100.